Unlocking the Future of Precision Manufacturing with CNC Machines and Industry 4.0 Insights

As industries navigate the complexities of modern manufacturing, the integration of CNC machines and Industry 4.0 principles is redefining precision manufacturing. According to a recent report by the International Federation of Robotics, the global demand for CNC machines is projected to grow at a CAGR of 6.2% between 2022 and 2028, highlighting their crucial role in enhancing productivity and accuracy in manufacturing processes. This growth is driven by advancements in automation technology and the increasing need for customized production to meet consumer demands.

CNC machines, equipped with advanced software and analytics tools, are at the forefront of this transformation. The World Economic Forum indicates that adopting Industry 4.0 technologies can lead to a productivity increase of up to 30% in manufacturing sectors. This paradigm shift allows manufacturers to leverage real-time data, optimize supply chains, and minimize waste, thereby unlocking unprecedented efficiencies. As companies invest in these technologies, the synergy between CNC machines and Industry 4.0 not only enhances operational capabilities but also positions manufacturers to innovate and compete in a rapidly evolving marketplace.

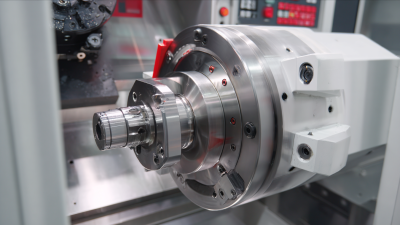

The Rise of CNC Machines in Precision Manufacturing

The rise of CNC machines in precision manufacturing is transforming the industry landscape, driven by remarkable market growth and advancements in technology. The global CNC machine market is projected to expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This surge is fueled by the increasing demand for high-precision machining solutions that cater to various sectors, including aerospace, automotive, and medical devices.

Additionally, the multi-axis machining centers market is set to witness a substantial increase, with an estimated size of $134.92 billion by 2033. This growth is indicative of manufacturers' shift towards sophisticated machining capabilities that enhance productivity and precision. Furthermore, the integration of artificial intelligence in CNC tools is expected to redefine market dynamics, addressing the rising need for automated and efficient production processes. As the precision tool market forecasts a jump from $220.43 billion in 2024 to $346.38 billion by 2033, the emphasis on high-quality manufacturing continues to reshape the competitive landscape within the industry.

Integrating Industry 4.0 Technologies for Enhanced Efficiency

The integration of Industry 4.0 technologies into precision manufacturing is revolutionizing the landscape of CNC machining. By harnessing advanced data analytics, IoT connectivity, and automation, manufacturers can significantly enhance operational efficiency and productivity. Real-time monitoring of machines allows for predictive maintenance, reducing downtime and ensuring that equipment operates at peak performance. As a result, manufacturers are not only able to respond swiftly to market demands but also optimize resource usage, minimizing waste and costs.

Furthermore, the implementation of smart machines enables a more agile production environment. With the ability to collect and analyze data, manufacturers can identify bottlenecks in their processes and make informed adjustments on the fly. This level of responsiveness leads to improved product quality and shorter lead times, ultimately increasing customer satisfaction. By unlocking the synergy between CNC machines and Industry 4.0 insights, businesses are poised to achieve unprecedented levels of precision and efficiency, aligning with the fast-evolving requirements of modern markets.

Impact of Data Analytics on CNC Operations and Decision Making

The integration of data analytics in CNC operations is transforming precision manufacturing by enhancing decision-making processes. Through real-time data gathering and analysis, manufacturers can monitor machine performance, predict maintenance needs, and optimize production schedules. This analytical approach allows for the identification of inefficiencies and bottlenecks, enabling a more agile response to changes in demand and production requirements.

Moreover, the incorporation of advanced data analytics tools facilitates smarter resource allocation and cost management. By leveraging insights derived from historical data, companies can forecast outcomes more accurately, reducing waste and improving overall productivity. The capability to analyze vast amounts of data also supports machine learning algorithms that guide CNC machines in adapting to complex designs and specifications, making the manufacturing process more responsive and precisely attuned to customer needs. As a result, organizations harnessing the power of data analytics can achieve higher quality products, increased throughput, and a more competitive edge in the precision manufacturing landscape.

Challenges and Solutions in Adopting Precision Manufacturing

The adoption of precision manufacturing through CNC machines and Industry 4.0 technologies presents several challenges that organizations must navigate. One significant hurdle is the high initial investment required for advanced CNC systems and the necessary infrastructure to support data integration and automation. Many manufacturers, especially small and medium enterprises, may struggle to allocate sufficient budget and resources, fearing the risk associated with such substantial upfront costs. Additionally, the skill gap in the workforce poses a threat, as specialized training is needed to operate these sophisticated machines and to utilize data analytics effectively.

To overcome these challenges, manufacturers can start by adopting a phased approach to integrate CNC technology and Industry 4.0 solutions. This strategy allows companies to gradually introduce automation, ensuring that employees receive the training they need without overwhelming existing processes. Furthermore, partnerships with technology providers can facilitate access to resources and expertise, enabling businesses to leverage innovative solutions like cloud computing and the Internet of Things (IoT). By addressing financial constraints and workforce readiness proactively, manufacturers can unlock the potential of precision manufacturing and position themselves for future growth.

| Dimension | Current Status | Challenges | Potential Solutions |

|---|---|---|---|

| Technology Adoption | Increasing integration of CNC machines. | High initial investment costs. | Government subsidies for technology upgrades. |

| Training and Skills | Workforce experienced with traditional methods. | Lack of skilled operators for CNC and Industry 4.0. | Comprehensive training programs and workshops. |

| Data Management | Emerging use of data analytics. | Integration issues with legacy systems. | Adoption of standard data formats and APIs. |

| Supply Chain | Tight-knit relationships with suppliers. | Disruption risks from global events. | Developing local supplier networks. |

| Quality Control | Established standards in place. | Inconsistent quality metrics across processes. | Implementing real-time quality monitoring systems. |

Future Trends: The Evolution of CNC and Smart Manufacturing Solutions

The evolution of CNC (Computer Numerical Control) machines is crucial in the landscape of smart manufacturing, driven by emerging technologies and innovative approaches. As industries embrace digital transformation, CNC machines are integrating artificial intelligence and robotics, revolutionizing precision manufacturing. AI optimization is enhancing machining efficiency, with self-optimized cutting approaches gaining traction in various sectors. This transformation indicates a sharp shift towards automation, fostering increased productivity and precision across diverse applications.

Emerging trends in the CNC machine market, including the growth of 5-axis machining centers, highlight a robust expansion fueled by these advancements. The market is anticipated to grow steadily, with a projected CAGR of 5.5% reflecting the rising demand for precision and productivity in manufacturing processes. As manufacturers adopt smarter solutions and circular economy practices, the industry is witnessing not only a technological evolution but also a cultural shift toward sustainable practices. This multifaceted progression promises to redefine manufacturing paradigms, positioning CNC technology at the forefront of modern industrial advancements.

Related Posts

-

Ultimate CNC Machine Showdown Unveiling the Best Options for Your Manufacturing Needs

-

Exploring CNC Turning Innovations at the 138th Canton Fair in 2025

-

Mastering the Craft of Structural Steel Fabrication A Step by Step Tutorial

-

Exploring Alternatives to CNC Laser Cutting Machines for Precision Manufacturing

-

Unlocking Growth Opportunities for CNC Fiber Laser Cutting Machines at the 138th Canton Fair in 2025

-

Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms